เรามีความหลงใหลในการแก้ปัญหา ที่แปลกใหม่ ที่นำวิสัยทัศน์ของคุณมาสู่ชีวิต

Bio-Pharmaceutical

Pharmaceutical cleanrooms in the United States fall under the oversight of the FDA, while in Europe they are regulated by the EMA. These pharmacy cleanroom facilities must comply with CGMP standards. According to the FDA, GMP encompasses the Current Good Manufacturing Practice regulations that the agency enforces. Compliance with CGMP ensures the identity, strength, quality, and purity of drug products through adequate control of manufacturing operations by medication producers within a pharma cleanroom environment. In essence, GMP promotes consistent product quality and safety in pharmaceutical cleanroom settings by emphasizing five core elements, commonly known as the 5 P's: people, premises, processes, products, and procedures.

Wiskind modular cleanroom systems have been utilized by various pharmaceutical manufacturers for their CGMP FDA validation cleanrooms. In pharmaceutical cleanrooms, filling rooms generally require a class 100/ISO5 pharmaceutical clean room classification, whereas other areas in the pharmacy cleanroom or pharma clean room may operate at lower classifications based on their intended functions.

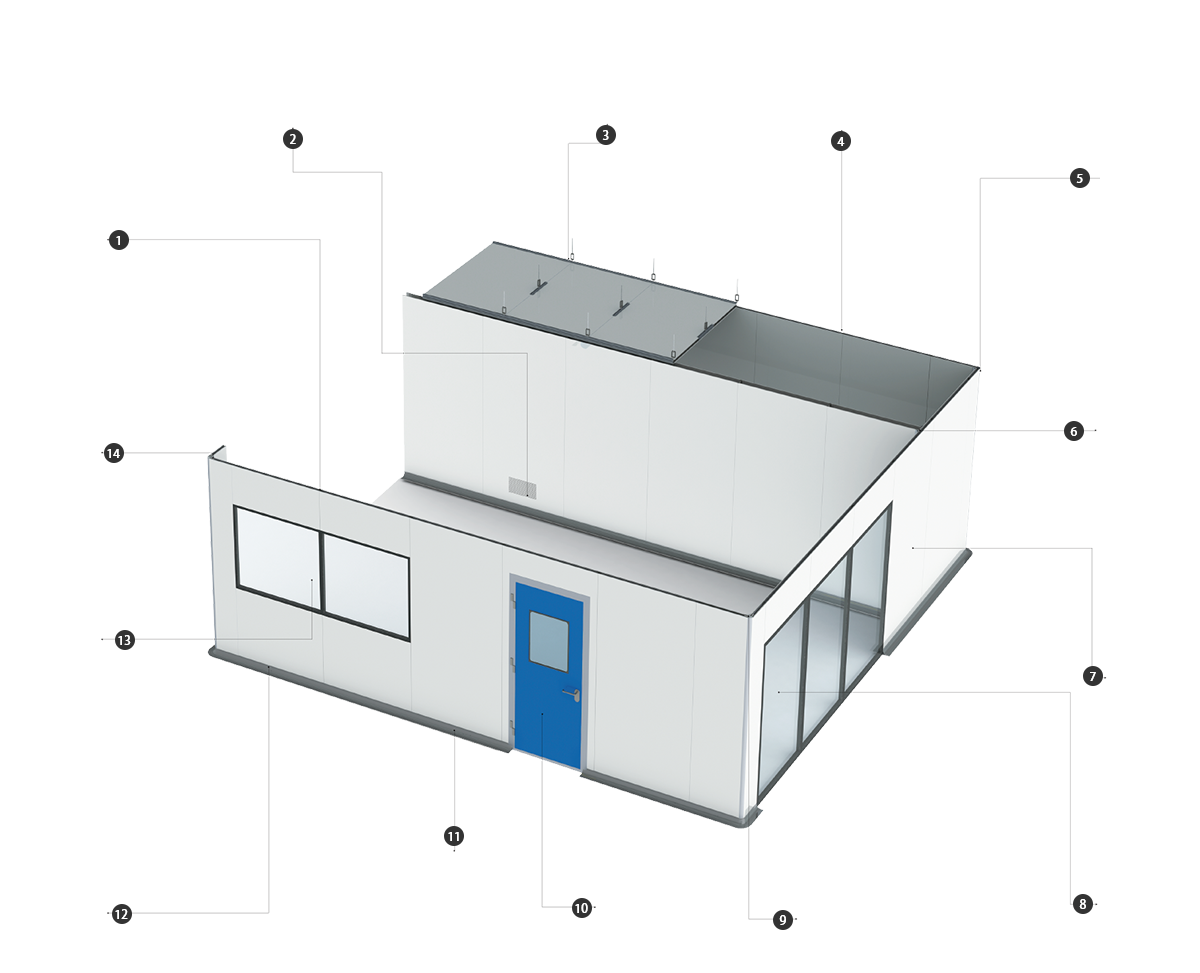

Key Components of Pharmaceutical Cleanrooms

Pharmaceutical cleanrooms typically incorporate several essential elements to ensure optimal performance and compliance. These include FRP modular walls designed for superior chemical resistance, room-side replaceable HEPA fan filterunits for efficient air filtration, FRP ceiling tiles for durability and cleanliness, heat-welded vinyl floors featuring integral coves to facilitate easy maintenance, as well as interlocked material transfer and gown rooms to maintain controlled access. Additionally, precise temperature and humidity control systems are integrated to support stable environmental conditions.

Q: What pharmaceutical clean room classification applies to pharmaceutical cleanrooms?

A: Pharmaceutical cleanrooms are typically ISO-5 (Class 100) for aseptic filling and sterile processes in a pharma clean room. Less critical areas often operate as ISO-6 (Class 1,000) or ISO-7 (Class 10,000). The EU GMP Annex 1 sets comparable standards, with slightly stricter requirements in key areas.

Q: What defines a CGMP pharmaceutical cleanroom?

A: A CGMP pharmaceutical cleanroom follows the Current Good Manufacturing Practices required by the FDA for pharmaceutical manufacturers. This standard exceeds basic Good Manufacturing Practices and raises the bar for design and operation within pharmaceutical clean room environments.

Q: How do ISO 14644 and EU GMP cleanroom grades differ in pharmaceutical cleanrooms?

A: ISO 14644 classifies cleanrooms by non-viable particle counts, such as ISO-5 allowing no more than 3,520 particles ≥0.5 μm/m³ at rest. EU GMP Annex 1 aligns these to operational grades: Grade A matches ISO-5, Grade B is ISO-5 at rest but ISO-7 in operation, Grade C is ISO-7 at rest and ISO-8 in operation, while Grade D is ISO-8 at rest. EU GMP further includes microbial limits, monitoring frequency, and recovery criteria absent from ISO standards.

Q: What flooring is most common in pharmaceutical cleanrooms?

A: Pharmacy cleanroom flooring must resist aggressive chemical agents that could otherwise damage the surface. It features minimal joints and cracks to avoid contamination traps and bacterial growth. Heat-welded vinyl with integral coves or epoxy coatings with a urethane top layer are the preferred choices for pharmaceutical cleanroom durability.

Q: What wall material is most common for pharmaceutical cleanrooms?

A: Pharmaceutical cleanrooms endure frequent harsh chemical cleaning of floors and walls alike. Fiber Reinforced Plastic (FRP) walls stand out for their strong resistance to these intensive cleaning regimens in a pharmacy clean room setting.

Q: What testing is standard for pharmaceutical cleanrooms?

A: Pharmaceutical cleanrooms require viable and non-viable particle testing. Settling plates detect microbial presence for viable monitoring, while laser particle counters measure airborne particulates for non-viable assessment in the pharmaceutical cleanroom.

Q: What ceiling materials suit pharmaceutical cleanrooms?

A: Pharmaceutical cleanroom ceilingsneed chemical resistance, HEPA filtration support, and a smooth, cleanable finish. FRP ceiling tiles or sealed gypsum panels coated with vinyl, paired with room-side replaceable HEPA fan filter units, deliver airtight integrity and simple upkeep in a pharma clean room.

Q: What role do pass-through chambers play in pharmaceutical cleanrooms?

A: Pass-through chambers consist of interlocked stainless steel or FRP units embedded in cleanroom walls to move materials, tools, or products between cleanliness zones without disrupting pressure cascades or risking contamination. They include UV lighting, HEPA-filtered purge cycles, and electronic interlocks so only one door opens at a time in the pharmaceutical clean room lab.

Q: How frequently must pharmaceutical cleanrooms be recertified?

A: Pharmaceutical cleanrooms undergo recertification at least every six months for ISO-5 zones and annually for ISO-6 through ISO-8 areas under FDA CGMP and EU GMP Annex 1. The process covers HEPA filter integrity via DOP/PAO testing, particle counts, airflow velocity and volume, pressure differentials, and microbial monitoring to verify sustained compliance in the pharmacy cleanroom.

ทำความสะอาดห้องเชี่ยวชาญในระบบปิดห้องทำความสะอาดระบบเพดานประตูห้องทำความสะอาด และหน้าต่าง และการพัฒนาผลิตภัณฑ์การผลิตการขายการให้คำปรึกษา และบริการ